%20(1).jpg?width=1680&height=952&name=unsplash_WYGhTLym344%20(1)%20(1).jpg)

ACCELERATING THE GLOBAL ENERGY TRANSITION WITH GREEN HYDROGEN

Green Hydrogen Systems designs and manufactures efficient, standardised and modular electrolysers for the production of green hydrogen with renewable energy.

learn more about us

HyProvide®

A-Series

Available in standardised, modular configurations for maximum efficiency, versatility and scalability, this next-generation technology makes the A-Series one of the most efficient pressurised alkaline electrolysers on the market.

The unit is designed from the ground up to accommodate the input fluctuations that come with renewable energy sources. Its versatile design allows for application across many different market segments for green hydrogen production.

Request a quote or product information, by filling out the below questions as precisely as possible, and we will connect you to one of our experts and get back to you.

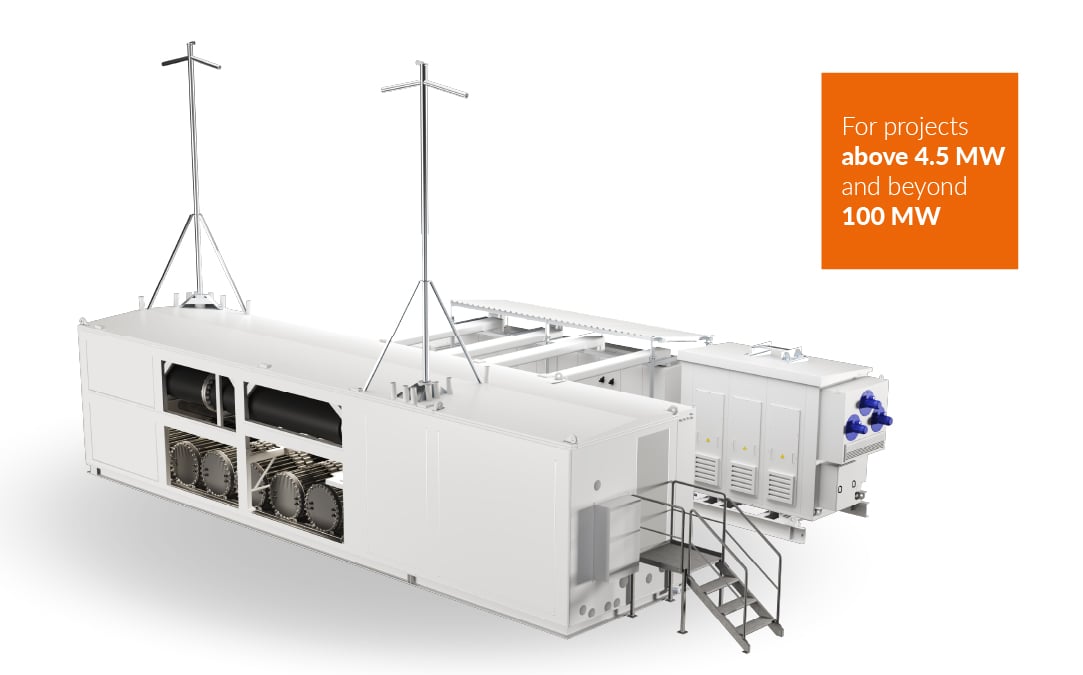

HyProvide®

X-Series

The X-Series is based on the existing well-proven technology, optimised for use in the growing market for large-scale applications in, for example, industry, energy and heavy-duty transport sectors.

Its unique multi-stack concept allows the electrolyser to reach higher voltages crucial to utilise mass-produced, low-cost and high-efficiency power electronics from wind and solar markets operating in the 1000-1500V range.

Read more about our

news & upcoming events

.png)

.png)

#8 reasons to choose our electrolysers

Mature Technology

Our products are built commercially proven pressurised alkaline technology

High Efficiency

One of the most efficient solutions on the market with competitive energy to hydrogen conversion

Modularity

Modular solutions that are suited for rapid scale-up, clustered solutions, and serial production

Dynamic Operations

The electrolysers are designed for renewable energy and operate dynamically at variable load rates

High durability

High durability (10+ year stack durability) and system uptime

High Output Pressure

The 30-35 bar hydrogen output pressure allows for a small product footprint and lower compression costs

Compact Design

Small footprint due to compact, modular design increasing the number of applications

Versatility

It's versatile allows application across many different market segments for green hydrogen production

See our

Selected projects

Electrolysis plant in an island mode

Project with Siemens Gamesa Renewable Energy. HyProvide® A60 electrolyser for on-site hydrogen generation. Complete turnkey delivery and commissioning by GHS.

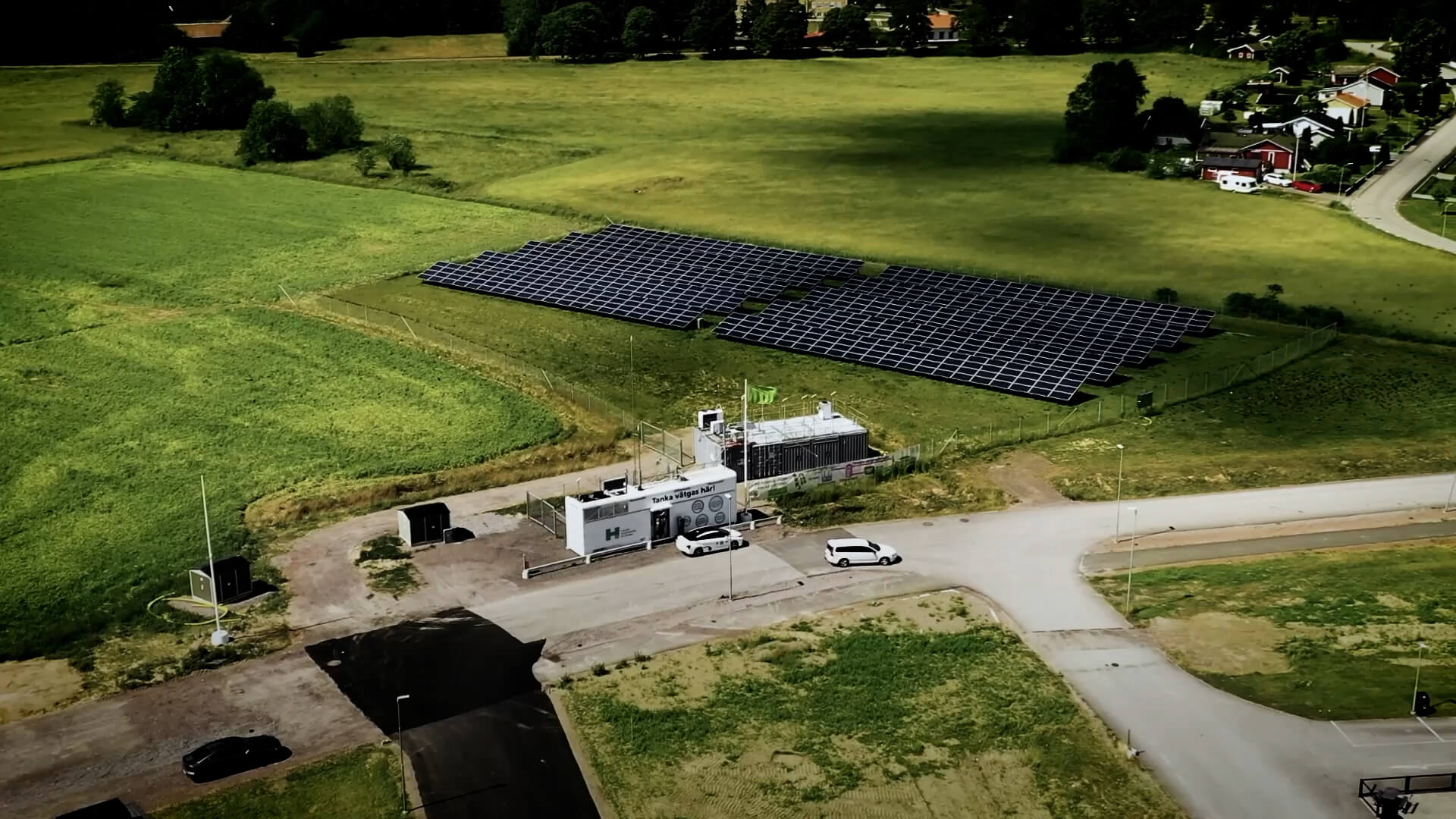

Electrolysis plant for a refueling station

Project with Mariestad Sweden & Nilsson Energy. HyProvide® A60 for the production of green hydrogen on-site for a hydrogen refuelling station – powered by solar energy to make 100% green hydrogen.

.png)

At Green Hydrogen Systems, my colleagues and I are convinced that green hydrogen will be at the heart of the future energy systems – and we are committed to be on the forefront of this energy transition.

Peter Friis

Interim CEO, Green Hydrogen Systems

.png)

.png)

.png)

.png)

.png)

.png)

.png)